Solvent-Based PU

Solvent-Based PU leather (also known as synthetic leather) is a high-performance synthetic leather material that has a similar appearance and texture to natural leather, It is made by high-performance resin and Organic Solvents, and after a complex processing process, it finally forms a soft, durable, breathable and wear-resistant material. It supports various pattern like printing, emboss imtation animal skin etc. according to customer requirments. It’s widely used for high-performance rainwear and technical outerwear, such as Mountaineering & Hardshell Jackets,Sailing & Offshore Gear and Waterproof Industrial Workwear

Our Service

- OEM / ODM Manufacturing Support

- Sample Order Service

- Quality Control & Performance Testing

- Cooperation Model & Ongoing Support

Dongguan Fuzhou Leather Co., Ltd.

Leather Manufacturer

Basic Info.

| Product Parameters | |

|---|---|

| Model Number | Solvent-based PU |

| Width | 137cm |

| Thickness | 0.4mm – 0.5mm |

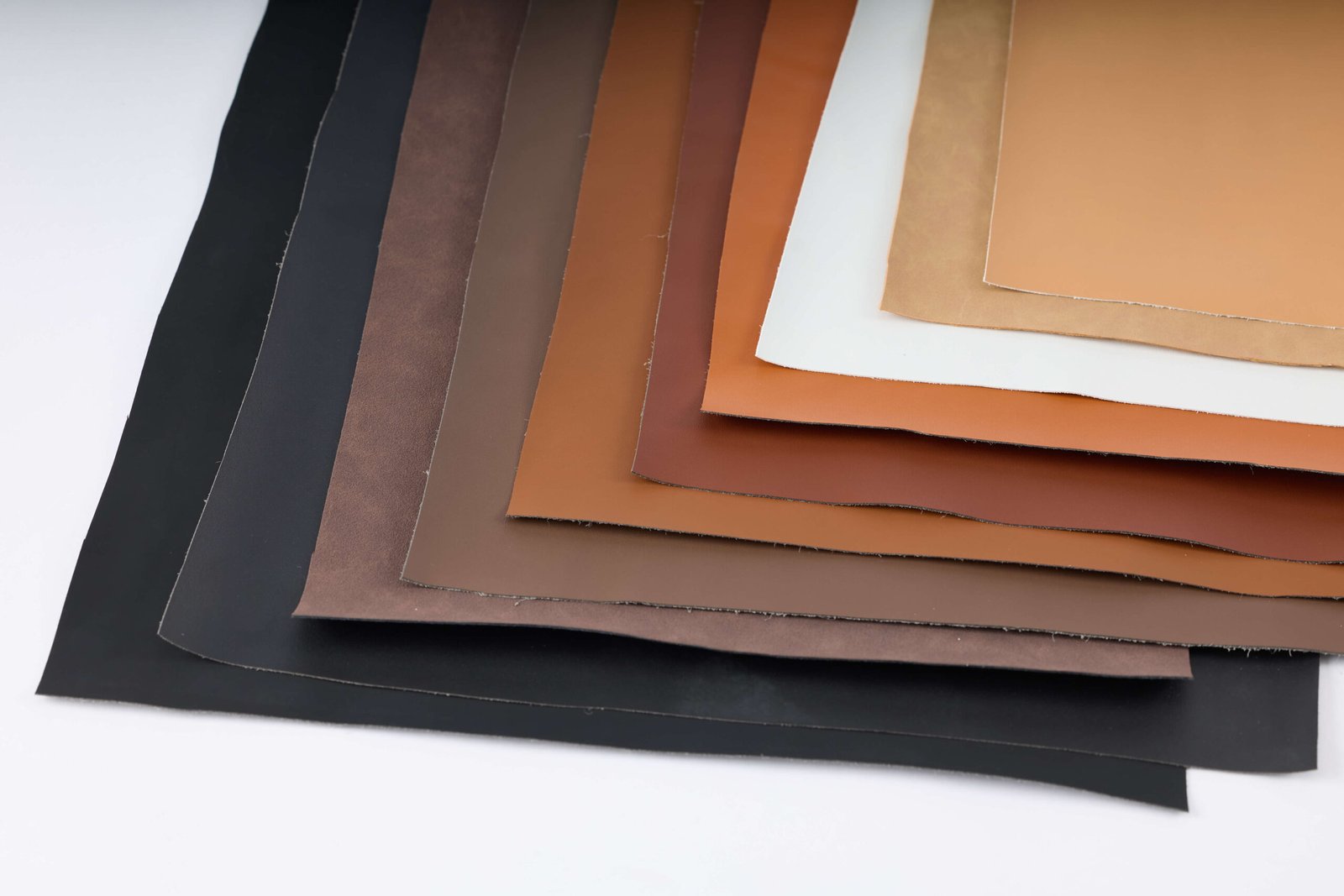

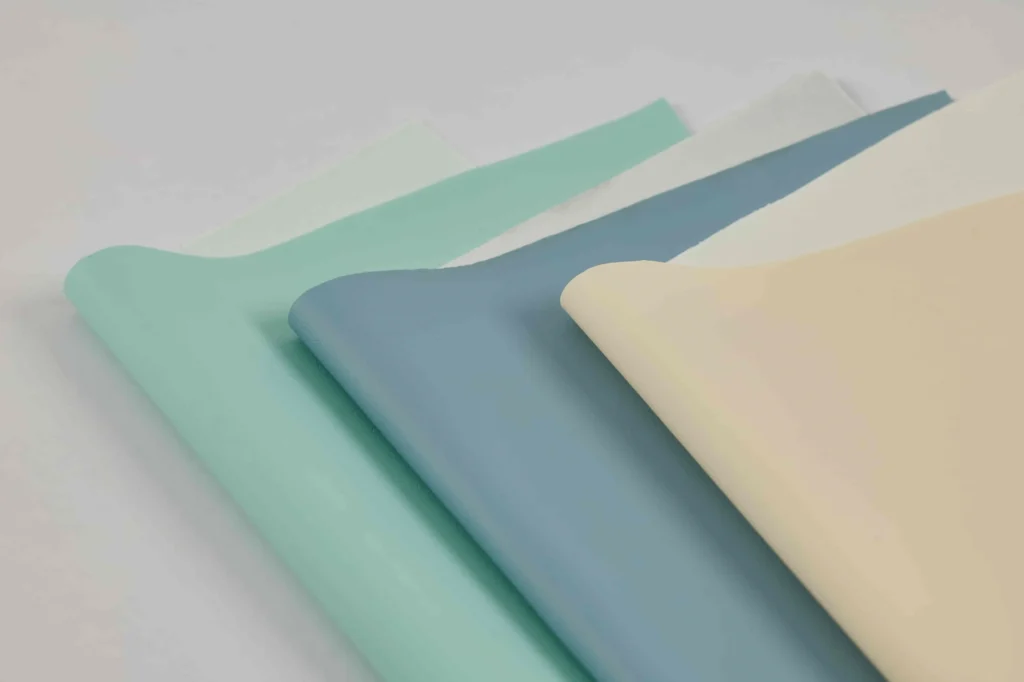

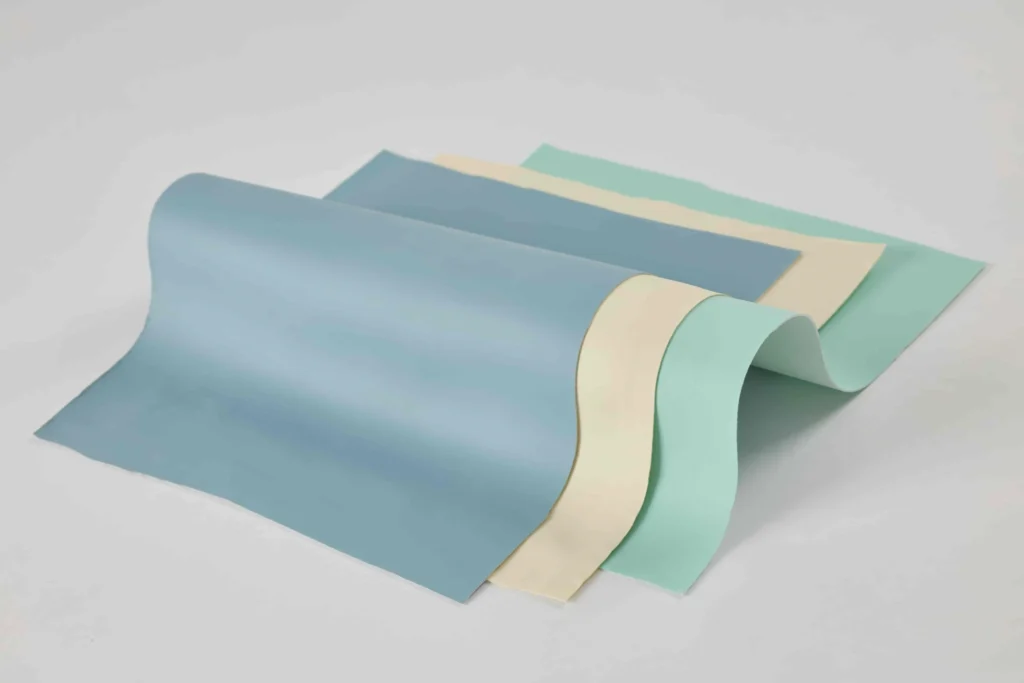

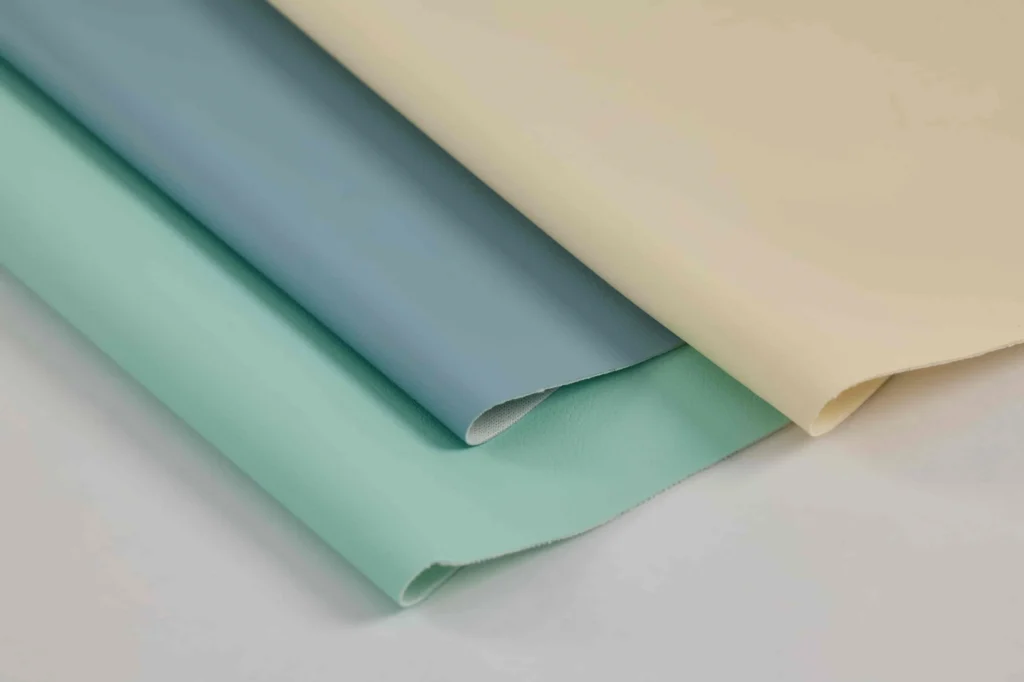

| Color | Customized |

| Backing | Knitted fabric, woven fabric, super-fine fiber base fabric, non-woven fabric |

| Pattern | Full-grain, imitation animal skins, fashion crackle, etc. |

| Technology | Release Paper |

| Material | PU Leather |

| MOQ | 800 meters / color |

| Application | Rainwear and technical outerwear, such as mountaineering & hardshell jackets, sailing & offshore gear, and waterproof industrial workwear |

| Feature | Waterproof, breathable, flame-resistant, abrasion-resistant, climate-resistant, durable, cost-controllable, compliant with industrial-grade safety standards |

| Eco-friendliness | Compliant with industry standards |

| Production Capacity | 150,000 meters / week |

| Product Weight | 170 gsm – 240 gsm |

| Packing | Roll |

| Payment Terms | T/T, 30% deposit, balance before shipment |

Packaging & Delivery

| Package Size | 145.00cm × 5.00cm × 5.00cm |

|---|---|

| Package Gross Weight | 1.000kg |

Product Description

Product Description

Performance Overview

Solvent-based PU leather is a performance-oriented synthetic material developed for applications that require durability, protection, and visual quality. It combines strong mechanical strength with reliable resistance to environmental stress, while maintaining a refined surface appearance and stable processing behavior. With mature manufacturing technology and controlled production costs, it remains a practical choice for demanding applications where long service life, consistent quality, and design flexibility are essential.

Surface textures and patterns can be customized based on customer requirements, including various embossing designs and decorative finishes, to meet different aesthetic and application needs.

Product Parameters

| Feature | Solvent-based PU Leather | Water-based PU Leather | Solvent-free PU Leather |

|---|---|---|---|

| Key Component | PU resin + organic solvents (DMF, MEK) | PU resin + water (60–70%) | 100% solid PU resins (no diluent) |

| Manufacturing Process | Coating → Drying / Oven (solvents evaporate) → Coagulation | Coating → Longer drying / oven (water evaporates) | Hot-melt coating → Cooling |

| Performance & Feel | Excellent. Soft, flexible, rich hand feel, high abrasion resistance. | Very good. Softer, more natural feel; often needs topcoats. | Excellent & consistent. High durability, strong adhesion; denser feel. |

| Environmental Impact | Good to industry standard | Very good | Excellent |

| Health | VOC emissions (air pollution, smog risk) | Low VOC, safer working environment | Zero VOC, no toxic solvents |

| Cost | Low–medium. Mature technology, rising due to regulations. | Higher. Slower drying, higher material cost. | Higher initial investment, cost-effective long term. |

| Applications | Rainwear, footwear, bags, furniture, automotive interiors | High-end apparel, raincoats, baby products, eco brands | Automotive interiors, electronics cases, medical & baby uses |

| Pros | Mature technology, strong physical properties, wide usage | Eco-friendly, soft feel, growing market demand | Truly green, highest consistency, strong bonding |

| Cons | Environmental pollution, health risks, shrinking market | Lower speed, higher cost, needs careful processing | High initial cost, limited suppliers, less flexible design changes |

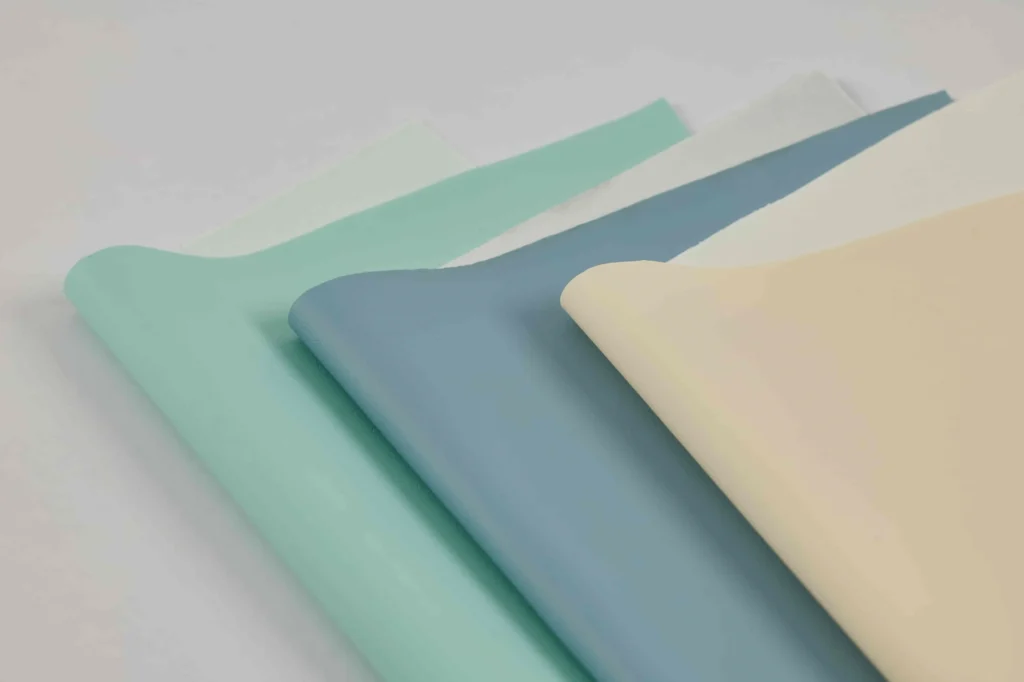

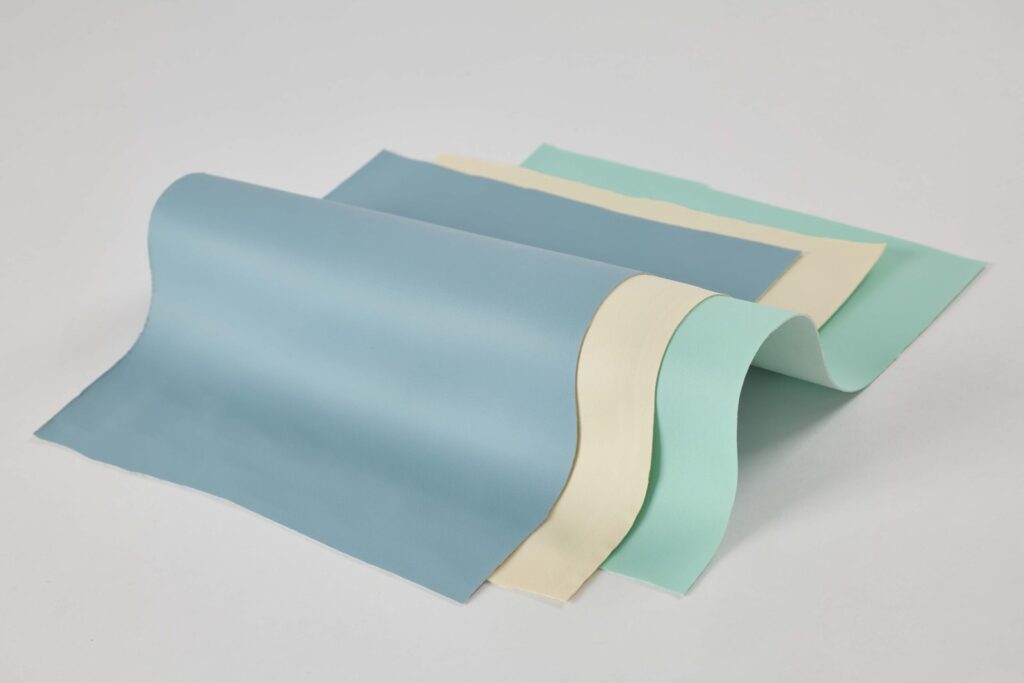

Detailed Photos

Long-Lasting Mechanical Durability

Engineered to withstand frequent movement and continuous use, the material offers excellent abrasion and impact resistance. It maintains structural integrity over time, reducing wear-related failures and supporting long-term product reliability in active or high-stress applications.

Reliable Protection in Harsh Conditions

The material delivers dependable waterproof performance and stable resistance to weathering, UV exposure, oils, and common industrial contaminants. These properties help ensure consistent performance in outdoor, industrial, and high-exposure environments where protection is critical.

Stable Adhesion and Surface Integrity

Its coating forms strong adhesion with a wide range of substrates, minimizing the risk of peeling, cracking, or surface delamination. This contributes to improved durability, consistent quality, and fewer surface-related issues throughout the product lifecycle.

Refined Appearance with Design Flexibility

With a soft, elastic hand feel and high surface clarity, the material offers a premium visual appearance while remaining flexible. It supports detailed embossing, printing, and customized surface finishes, allowing designers to achieve diverse textures, patterns, and aesthetic effects without compromising performance.

APPLICATIONS

Solvent-based PU leather is widely used across multiple industries where durability, surface stability, and consistent appearance are required. It is commonly applied in rainwear and protective garments, footwear and bags, upholstered furniture, and automotive interior components. Its balanced performance in abrasion resistance, waterproof protection, processing compatibility, and surface finish makes it a reliable material choice for both functional and decorative applications.

FAQ

Q1: What products do you specialize in, and which applications do you focus on?

A: We specialize in medium- to high-grade PU/PVC synthetic leather, including solvent-based PU, water-based PU, solvent-free PU, semi-PU, silicone leather, and microfiber leather. Our materials are primarily used in rainwear and technical outerwear, footwear, bags, furniture upholstery, and selected automotive interior applications, where durability, surface stability, and consistent quality are required.

Q2: Do you support OEM customization for material specifications and surface designs?

A: Yes. We support OEM and application-oriented customization, including thickness, backing fabric, surface texture, embossing pattern, color matching, and functional requirements. Materials can be developed based on your end-use application and processing method to ensure stable performance in mass production.

Q3: What is your minimum order quantity (MOQ) and typical lead time?

A: Our standard MOQ is 800 meters per color. Lead time depends on material type and customization level, but typically ranges from 10–15 days for standard items and 15–25 days for customized specifications after sample approval.

Q4: How do you ensure product quality and batch consistency?

A: We follow standardized production and inspection procedures throughout the manufacturing process. Finished products undergo visual and functional inspections, and raw materials are traceable to ensure consistent quality and reduced batch variation for long-term supply projects.

Q5: Can you provide samples for evaluation before bulk orders?

A: Yes. We provide material samples for evaluation prior to bulk production. Sample sizes are usually based on our sample catalog, and A4-size samples can be provided for testing, prototyping, and internal approval when required.

Q6: What payment terms and cooperation models do you offer?

A: Our standard payment terms are T/T with a 30% deposit and the balance paid before shipment or against B/L copy. For long-term or repeat customers, flexible terms can be discussed based on cooperation history and order volume.

- Business Type:

Leather Manufacturer/Tarding

- Main Products:

PU Leather(Solvent-Based PU、Water-Based PU、Solvent-free Synthetic PU Leather )、Semi-PU Leather 、Slicone Leathe、Microfiber Leather

- Year of Establishment:

2006

- Number of Employees:

200+

- Address:

Factory: Shenzhou Rd W, G319, Industrial Park, Yongxin County, Ji’an City, Jiangxi Province, China

Branch office :Room 1601-1610, Building 2, Wanda Plaza, No. 6 Kngle North Road, Houjie Town, Dongguan City Guangdong Province, China

Dongguan Fuzhou Leather Co., Ltd. has been a premier manufacturer and exporter in the synthetic leather industry since its founding in 2006. Backed by a substantial investment of 50000000CNY , our company specializes in producing medium and high-grade PU/PVC synthetic leather and related fabrics. Our Dongguan-based office is to oversee and conduct our foreign trade business, . We are proud to have achieved a remarkable sales milestone of USD 1.6 billion, a testament to our commitment to excellence and customer trust. We can carry out full-scale production of 3 special series of products as following: I. Water resistant leather II. Sofa & Upholstery leather III. Bicycle and car seat cushion leather and our materials comply with EN71-3, RoHS, REACH 53 and ASTM To meet diverse client needs, FuZhou’s synthetic leather offers distinct advantages, including a premium genuine leather feel, cost-effectiveness, and a wide range of unique, differentiated effects. It serves as an ideal material for various applications such as rainwear, garments, automotive seat covers, furniture, bags, belts etc. Additionally, we provide a diverse selection of patterns on a PU base. Our primary market are USA, Danmark, Jermany, Africa, Domestic China and we have established strong, long-term partnerships with a loyal customer base both domestically and internationally.

- Business Type:

Manufacturer/Tarding

- Main Products:

PU Leather(Solvent-Based PU、Water-Based PU、Solvent-free Synthetic PU Leather )、Semi-PU Leather 、Slicone Leathe、Microfiber Leather

- Year of Establishment:

2006

- Number of Employees:

200

- Plant Area:

20000 m²

- Registered Capital:

50,000,000CNY

- Annual Turnover:

1.6 billion CNY

- Address:

Factory: Shenzhou Rd W, G319, Industrial Park, Yongxin County, Ji’an City, Jiangxi Province, China

Branch office :Room 1601-1610, Building 2, Wanda Plaza, No. 6 Kngle North Road, Houjie Town, Dongguan City Guangdong Province, China

- International Commercial Terms(Incoterms):

FOB, CIF, CFR, EXW

- Terms of Payment:

T/T, Western Union

- Nearest Por:

Sekou port, Yantian port

- Major Market:

USA, Danmark, Jermany, Africa, Domestic China

- Inspection Type for Finished Products:

Random inspection(Visual inspection & Function inspection)

- Inspection Method for Finished Products:

Have instructions and uniformly followed

- QA/QC Inspectors:

10 people

- Traceability of Raw Materials:

Yes

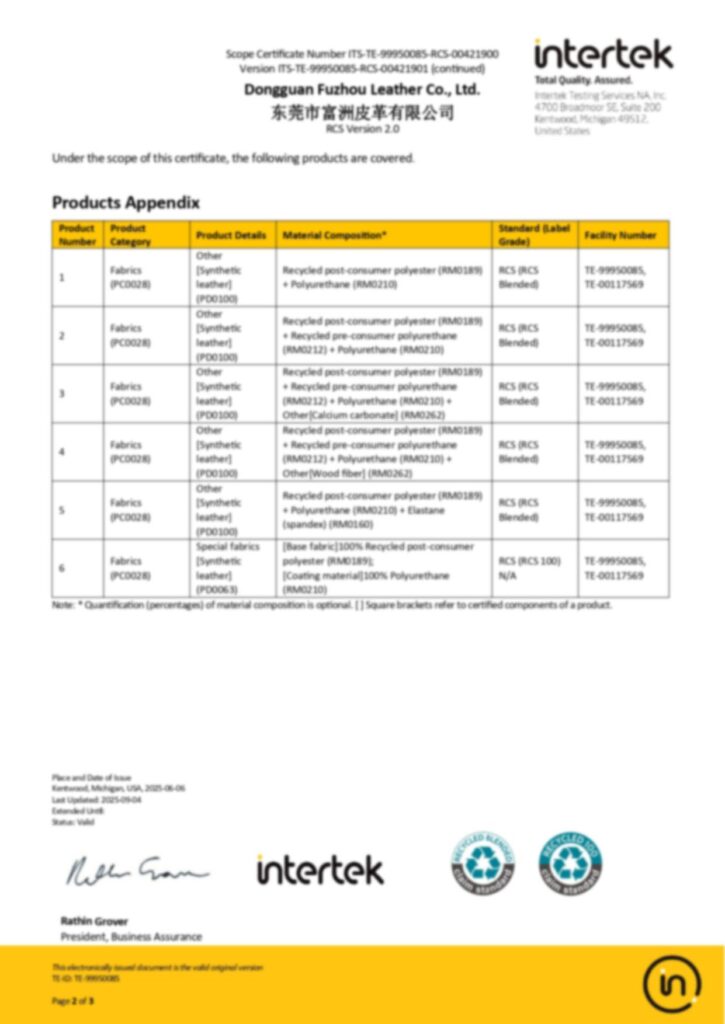

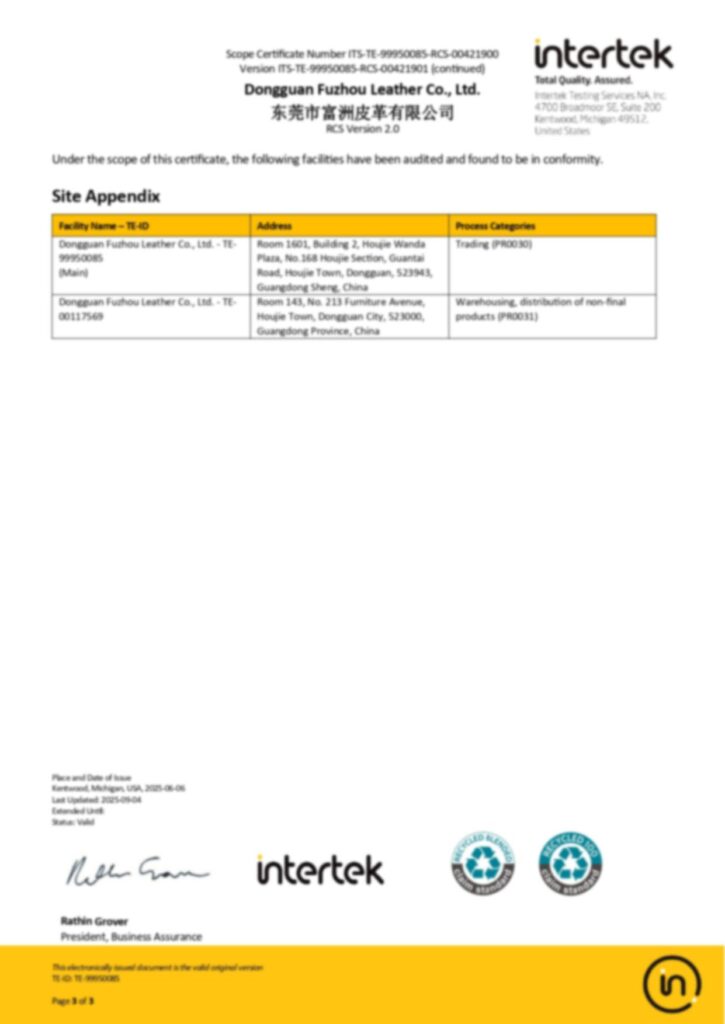

PDF version certificate

CERTIFICATE

OEKO Certified

Intertek Certified

Intertek Certified

Intertek Certified

CERTIFICATE

CERTIFICATE

COMPANY

Dongguan office

COMPANY

COMPANY

COMPANY

OUR TEAM

CEO

R&D specialist

Customer specialist

WORKSHOP

WORKSHOP

WORKSHOP

WORKSHOP

WORKSHOP

PRODUCT

PRODUCT

PRODUCT

PRODUCT

PRODUCT

Dongguan Fuzhou Leather Co., Ltd.

Semi-PU Leather

800Meters (MOQ)

Silicone leather

800Meters (MOQ)

Solvent-free PU leather

800Meters (MOQ)

Water-Based PU

800Meters (MOQ)

Microfiber Synthetic Leather

800Meters (MOQ)